Find out more at REMONDIS PMR

Search

REMONDIS Group locations

Discover the world of REMONDIS with its 1,000+ branches and associated companies in more than 30 countries across Europe, Africa, Asia and Australia.

Catalyst recycling – always worth its while

Catalysts are the backbone of many industrial products and have become indispensable in various industrial processes. However, under the harsh conditions of production, catalysts lose effectiveness over time and are therefore not infinitely usable. When processes are no longer economical due to quality standards or efficiency requirements, the catalysts have been spent and reached their “end of life”. Whether due to poisoning, fouling, thermal degradation or mechanical attrition - spent catalysts will need to be replaced to maintain running operations.

This means there is a steadily increasing need for catalyst recycling. This is all the more true when precious metals such as platinum, palladium, rhodium, gold or silver as well as transition metals such as molybdenum, nickel, cobalt, copper, vanadium or zinc are used as catalyst material. This is often the case in the pharmaceutical, petrochemical and specialty chemicals industries and holds especially true for oil refineries.

At our sites in Moerdijk (Netherlands) and Dorsten (Germany), we recover these metals from catalysts as well as from filter cakes, ash, sludge and cleaning residues from catalyst-related processes. Recovering the metals in the course of catalyst recycling not only pays off in terms of resource protection, but is also simply worthwhile from an economic point of view.

A full range of catalyst recycling services

Logistics

Notification and formalities

Interim storage

Thermal treatment

Grinding, screening

Metal Identification

Transfer of precious metal

Metal Forecast

Bespoke advice – the be-all and end-all of our catalyst recycling services

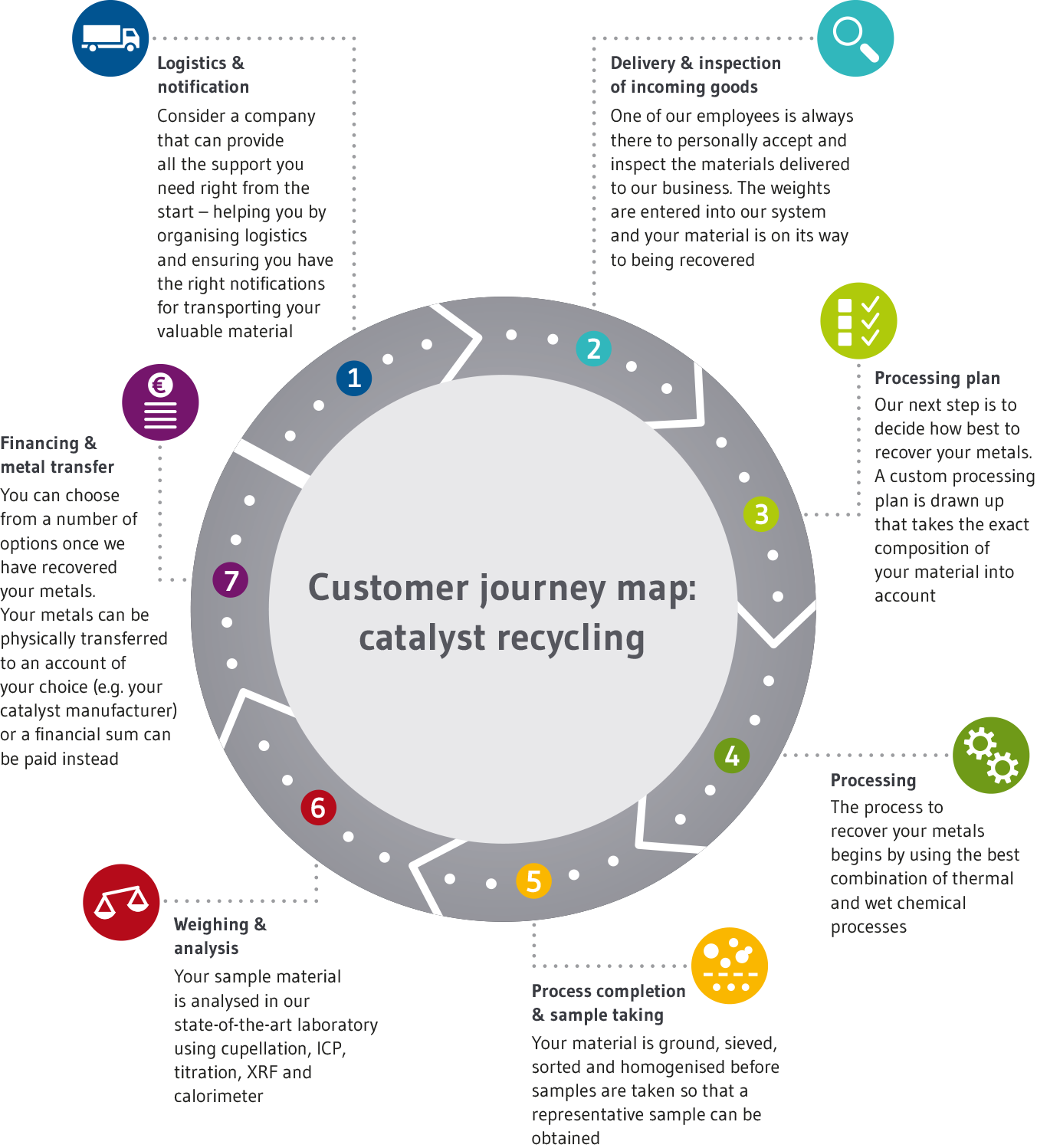

Our objective is to find the most efficient solution for your business. This involves us first getting to know exactly what you want and need and assessing your material. We then use this information to draw up a tailored offer that meets your exact requirements. This lists all relevant parameters (such as terms of payment, recovery rates, treatment costs and logistics services), enabling you – right from the start – to calculate exactly how you benefit from having your catalyst recycled. Why not try it out for yourself and see how it works?! All you need to do is contact us.

Our company has been issued ISO 14001:2015 and 9001:2015 certifications and we have been accredited by the London Bullion Market Association (LBMA). Furthermore, we have been awarded silver by the EcoVadis Sustainability Rating and are a member of the Responsible Minerals Initiative.

Why our catalyst recycling operations stand out from others

Not only can we process standard waste streams produced from plant shut downs but we can also handle exceptionally difficult materials that are pyrophoric, highly energetic or loaded with sulphur. Every material lot is assessed and treated individually to make sure we use the best recycling parameters for your specific material. Flexible operations and new innovative recovery techniques allow us to recover metals from both homogenous and heterogeneous catalysts. This provides our customers with several different benefits – and singles us out from other catalyst recyclers.

Fast & uncomplicated

Being a separate, independent business within the REMONDIS Group, we are able to adapt our services to meet your exact requirements. This allows us to react quickly and provide you with the help you need within no time at all.

Highly flexible

From small to large quantities of material – we can take it and treat it. We can do this as we have access to the REMONDIS Group’s network of plants and facilities, enabling us to respond flexibly to our customers’ requirements.

High levels of security

Both the excellent security systems in our facilities and our comprehensive insurance management ensure that your valuable material is kept safe at all times.

Experts for the more difficult cases

We have extensive experience of handling all kinds of hazardous substances and have transport permits covering the whole of Europe. From logistics to waste management – you can be sure your material is always in safe hands.

Highly innovative

We are continuously carrying out research and development work and always looking at ways to further improve our operations. The result: state-of-the-art recovery processes with minimum material loss and high levels of efficiency.

Payment for or return of metals

The value of your recovered material is calculated to the exact gram and then credited to your account. Alternatively, we can return the high-purity recycled precious metal to you so you can re-use it as a catalyst material.

A few details about catalyst recycling at REMONDIS PMR

We deploy very high technological standards. Some of our processes – such as the refining carried out in our specialised annealing furnaces using indirect heating technology and pyrolysis – are unique and provide our customers with a whole range of solutions and possibilities.

Transparency and security – two top priorities

Each individual stage of the process is documented in detail – all the way through to the final recovery stage and payment procedure – and, if you want, you can visit us to see exactly how we work. We are also able to take samples of your materials at your business whenever you wish – either as a random test or to check each batch. If you wish, we can also provide you with written proof of the analysis results in addition to the consignment collection note. What’s more, there is no safer place for your precious metals than at our facility in Moerdijk. The whole of the building is effectively a maximum security unit – with concrete walls, bulletproof windows and a 5-metre fence around the whole of the grounds.

Other security measures include:

An extensive accreditation system for all areas of the premises in Moerdijk

All incoming and outgoing materials are weighed and registered for each individual batch

All precious metals are stored in our central vault (equipped with an electronic lock)

A comprehensive 24-hour alarm and CCTV surveillance system

As a specialist in hazardous waste and metal containing wastes, we ensure that pollutants are disposed of in a labour and environmentally friendly manner while ensuring that valuable materials are recovered. In doing so, we strictly ensure compliance with all legal regulations without losing focus on environmental protection, recycling quality and efficiency.

The environment and respect for human rights are extremely important to us, which is why we fundamentally do not accept any conflict minerals. You can find our declarations here: